Integrated forming smart running yarn nozzle computerized flat knitting machine uses a bottom plate, and the secondary roller, in coordination with the flexible pulling device, completes the entire garment seamlessly, eliminating processes such as seaming and stitching.

The new flexible pulling mechanism, in conjunction with the bottom plate and secondary roller, better meets the fabric's needs for clearing stitches, collecting stitches, dropping stitches, transferring stitches, twisting flowers, and localized weaving.

Independent control of 16 electric yarn nozzles allows horizontal movement, precise positioning, and synchronized yarn feeding. This reduces empty machine head strokes, easily achieving special pattern organizations such as inlaying flowers, reverse yarn addition, weft interfacing, hollowing, raising flowers, and full-form weaving, thereby increasing the diversity of patterns throughout the process.

The ultra-small 5.2-inch motorized head enhances machine stability and efficiency with features like motorized stitch reversal, motorized direction change, and rapid head rotation.

Yarn Storer:

Uses a carbon brushless DC motor controlled by a microprocessor. Yarn storage is monitored by sensors, adjusting the winding motor speed based on yarn usage to ensure smooth yarn output. The magnetic tension device at the yarn exit guarantees consistent yarn tension.

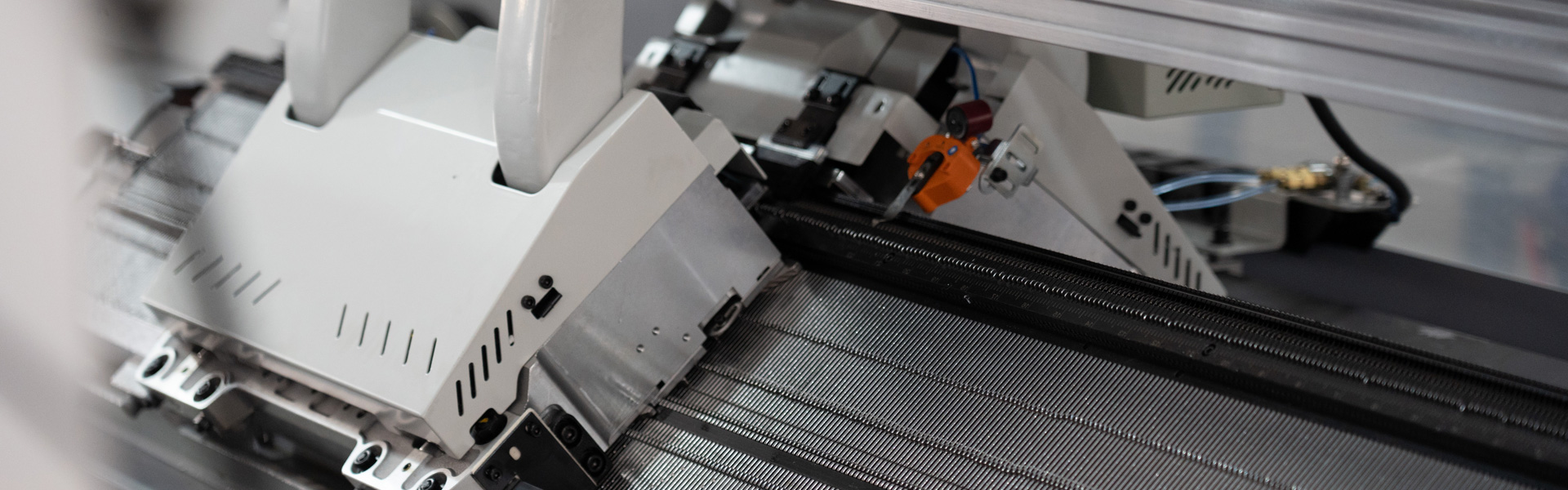

Electric Yarn Nozzle:

16 yarn nozzles, independent of the machine head, move horizontally and are precisely positioned by an encoder's feedback control. Coordinated with the system's individual control, they enter the knitting area accurately, reducing empty machine head strokes and increasing knitting efficiency. It can achieve specific pattern knitting.

Flexible Pulling Device:

Replaces the traditional high-position sinker with multiple electric crawlers, allowing segmented and zone-adjustable control of individual electric crawlers. This effectively controls the local tension of the fabric, enabling the knitting of seamless garments with various three-dimensional and different organizational structures.

Machine Head:

Utilizes a 5.2-inch fully motorized small head to enhance machine stability, reduce rotation distance, and increase knitting efficiency.

Automatic Lubrication:

The fully automatic lubrication device, with a system-determined lubrication time, automatically lubricates the long needle spring on the needle plate. This avoids uncertainties in manual lubrication frequency and quantity, significantly extending the machine's lifespan.

HPSS (High Production System Smart Yarn Selector):

Single machine head with three systems, this series includes both bottom plate and non-bottom plate automatic computerized flat knitting machines. Using digital

| Needle Gauge | 3.5.2G, 6.2G, 7.2G, 9.2G, 10.2G |

| Knitting Range | 72 inches, 82 inches |

| Selector | 8-stage electronic selector |

| Machine Speed | Up to 1.4 meters/second. Knitting speed varies with the number of needles and knitting conditions, adjustable speed |

| Knitting System | Single-Head Triple System |

| Shaker Bed | Servo motor precision control, 2-inch needle shift range |

| Stitch Density | High-speed stepping motor control, dynamic stitch density function, multi-stage arbitrary setting |

| Tension Device | Flexible device, bottom plate, and auxiliary roller work together, multi-stage arbitrary setting |

| Motor Reversal | Motor connecting rod reversal with selector avoidance and simultaneous optimization, achieving rapid and smooth head reversal |

| Antenna Stand | Submerged antenna stand. Stops in case of major knots, lowers to the speed at the time of detection error when encountering small knots, and automatically returns to the original speed after weaving 0-99 rows set by itself. |

| Color Change System | 16 electric yarn feeders |

| Automatic Stop | Automatically stops for broken yarn, major knots, fabric rolling, needle collision, completion of specified quantity, overload, program errors, etc. |

| Safety Device | Safety cover to prevent dust and reduce noise. Also equipped with emergency stop switch and emergency power cutoff device. |

| Machine Size and Weight | 72-inch dimensions: Length * Width * Height 3500mm * 880mm * 2010mm Net weight: Approx. 1500kg 82-inch dimensions: Length * Width * Height 3750mm * 880mm * 2010mm Net weight: Approx. 1600kg |

| Power Supply Unit | Voltage: AC220V/380V Frequency: 50HZ/60HZ Power: 1.5KW |