HPSS (High Performance Stitch System) for Floor Installation

Product Details +

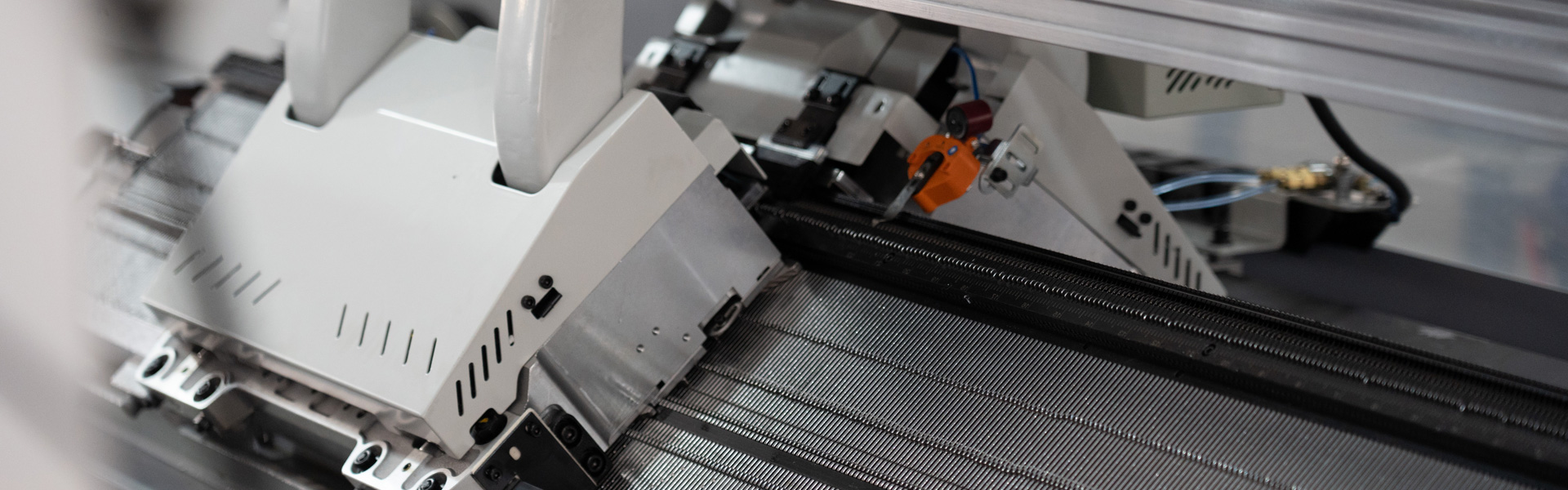

This series is equipped with advanced bottom plate and yarn clipper devices. The bottom plate device utilizes the principle of active release, allowing the closed compound needle to effectively perform its yarn-hanging and yarn-removing functions. The yarn clipper device and the bottom plate device complement each other; their collaborative operation is essential to fully realize their intended functions, effectively reducing yarn wastage and enhancing production efficiency. The series incorporates digital technology, enabling the flat knitting machine to perform functions such as stitch reversal, stitch hanging, hole picking, inlaying, visible and invisible stitch picking, and other regular pattern knitting. It can knit basic knitting structures (such as flat knitting and single-sided knitting), as well as multi-color irregular patterning, and twisting patterns in the weft knitting structure.

Technical Parameter +

Product Specifications

| Model | Knitting Width | Length | Width | Height | Net Weight |

| HPSS-52F | 52 inches | 2850 | 934 | 2010 | Approx. 1200kg |

Main Parameters

| Needle Gauge | 5G, 6G, 7G, 8G, 9G, 10G, 12G, 14G, 16G |

| Knitting Width | 52 (inches) |

| Voltage | 220V |

| Roller | Single Roller, Double Roller |

| Power | 1.0kw |