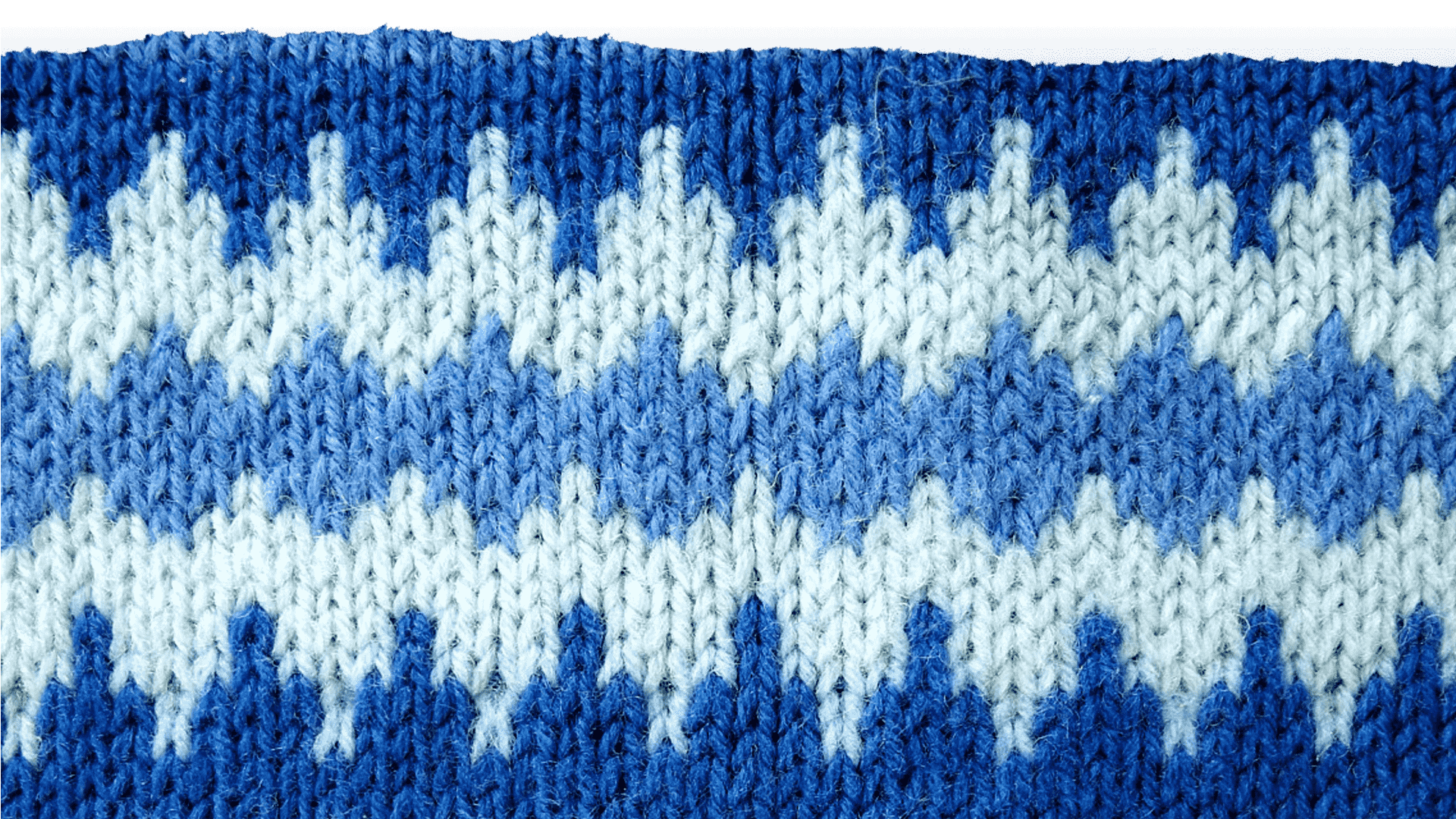

The company always adheres to the philosophy of "Stability through Quality, Innovation through Technology," persistently creating computerized flat knitting machines with "high performance, high efficiency, low failure, and low energy consumption." Quality is the lifeblood of the enterprise, and this is the consistent management philosophy of Tongcheng Textile Technology. With the mindset of "achieving others is achieving oneself," we introduce advanced technology from seamless computerized flat knitting machines abroad, which can be remotely controlled through the Internet. Starting from customer requirements, paying attention to details, treating people with integrity, we sincerely serve customers. We solemnly practice the commitment of "governing with virtue, exhibiting the industry with integrity," placing customer interests at the forefront and creating maximum value for customers.